Have any questions?

Leave a message and we will answer you:

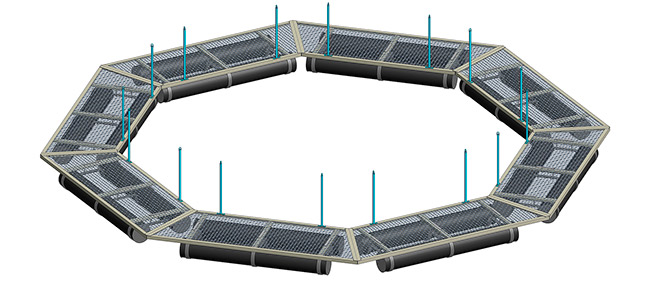

Nylon Net Pens (plastic)

High-density polyethylene (HDPE) cages are widely used, because of the versatility of the materials used

Global aquaculture production has been steadily growing in recent decades, increasingly contributing fish and other edible aquatic organisms of commercial importance entering national, regional and international markets.

The growing demand for such products has stimulated the development and expansion of aquaculture production systems both on land and in all waterbodies, covering technologies ranging from the production of seed material to ongrowing structures and other farming support facilities.

High-density polyethylene (HDPE) net pens are widely used, because of the versatility of the materials used, the relative simplicity in the performance of the various farming operations, and the comparatively limited investment capital required.

Technological improvements of HDPE cages are evolving with the availability of new materials and the various equipment items needed to service all farming operations.

Benefits polyethylene cage fish farming:

- Low cost relative to fish farming in earthen ponds or CCTV system;

- Management easier and less costly;

- Ease of observation and study of fish nutrition and health;

- Easy and economical treatment against parasites and diseases;

- Compared to earthen ponds and CCTV system requires less investmen;

- In the case of environmental pollutants and suspended solids, which can be problematic for the cage, the cage can be moved.

HDPE is known for its large strength-to-density ratio.

HDPE is known for its large strength-to-density ratio. The density of HDPE can range from 0.93 to 0.97 g/cm3 or 970 kg/m3. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength than LDPE. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength. It is also harder and more opaque and can withstand somewhat higher temperatures (120 °C/ 248 °F for short periods). The physical properties of HDPE can vary depending on the molding process that is used to manufacture a specific sample.

High-density polyethylene (HDPE) floating cages are currently widely used in modern industrial marine aquaculture in many parts of the world owing to the versatility of the materials used, the simplicity in the various farming operations and the relatively contained investment capital required. The main structural elements of these cages are the HDPE pipes, which can be assembled in various ways in order to produce collars of different sizes and shapes. The HDPE pipes, held together by a series of brackets with stanchions disposed throughout the entire circumference, form the floating collar ring, which is the main structure on which the fish net pen is secured. These gravity cages maintain the net pen shape and volume through a system of weights, also known as a sinker system, fixed at the bottom end of the net.

Our knowledge and experience allows us to make custom net pen in any dimension using any type of material. You can configure the net pen to meet your requirements.

HDPE pipes are an excellent material for cage construction because they are durable, flexible, shockproof, resistant to ultraviolet (UV) light and require relatively little maintenance, if installed correctly. Luxsol® has got a professional crew to mount and maintain High-density polyethylene (HDPE) net pens.

High-density polyethylene (HDPE) fish farming accessories:

Mooring systems.

The mooring system used with the HDPE circular cages is a square-shaped grid system held on the sea bed with an array of mooring lines. It is a dynamic system; all of the components keep the structures moored to the sea bed, and are designed to dampen the forces generated by the wave motion. The mooring system is divided in two main groups of components, the mooring lines and the grid system:- The mooring lines include the anchors, ground chains, ropes and related shackles, and buoys.

- The grid system includes the frame ropes, mooring buoys, connector rings or plates, bridles, and related shackles/

Net connecters – loops, rings and zippers.

Any knots or splices in a rope will reduce the breaking load. Splicing is the most reliable way of connecting two ropes and retains the highest percentage of the breaking load. Splicing is therefore recommended for all attachment points on the net. The ropes of the net cage are provided with a number of connection points that will allow the proper installation of the net onto the collar, the handrail, the sinker system and any other cage component that needs to be connected with the cage net. Each of these connections will have different requirements regarding strength and abrasion resistance.Bird nets.

The most efficient way to prevent bird predation is to cover the open top of the cage with a bird net. This net should have a large mesh size and be mounted with a rope running along the perimeter of the cage. Additional diagonal cross ropes may be added for strength.Brackets.

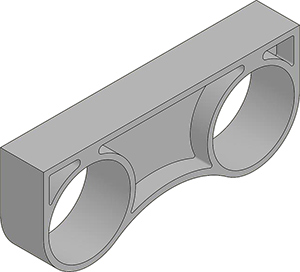

The bracket is a structural element of the cage collar that binds the pipes together to form the cage collar. Bracket robustness is essential to cage reliability. The bracket design may include two or three (sometimes even four) seats for the main floating. Additional spaces for walkway pipes may be available. On the top of the stanchion, a seat is available where the handrail is lodged. The brackets may be equipped with specific attachment points for the net and sinker system, which can be secured with lines or ropes. This last point may also be used to attach a perimeter safety chain that can act as additional security to prevent the collar breaking apart in heavy seas.

How much does HDPE net pen cost? |

|